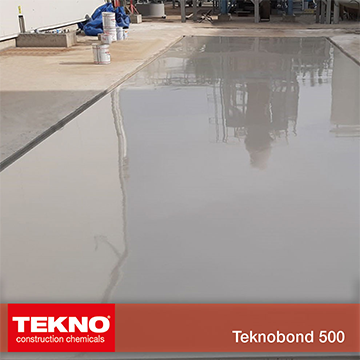

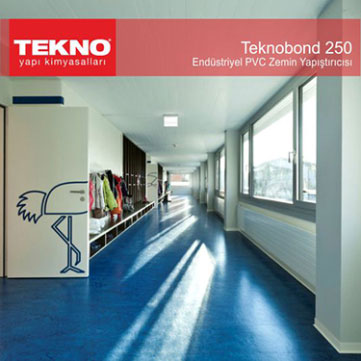

Solvent Free, 3 components, floor coating material which is combination of special graded aggregates and high strength polyurethane resins

Solvent Free, 3 components, floor coating material which is combination of special graded aggregates and high strength polyurethane resinsAreas of Usage

• in hospitals, shopping centers, schools, offices, showrooms, rest rooms and areas where rubber-wheeled vehicles are in use

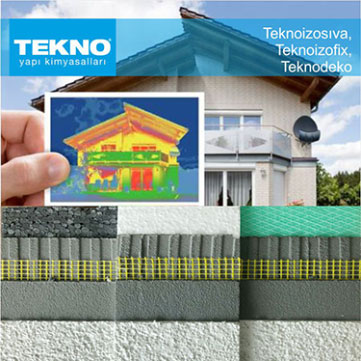

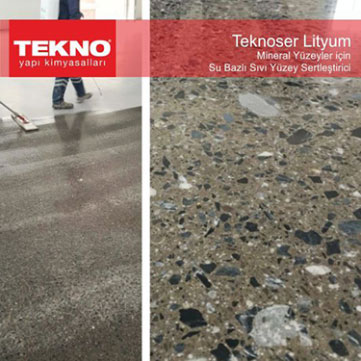

• Far levelling and smoothing new or existing concrete, marble, and ceramic substrates,

• Abrasion-resistant floors on concrete, old terrazzo, ceramic tiles and natural stones.

• Terrazzo, inside homes, offices, shops, museums, theatres and exhibition halis when used in combination with natural aggregates.

Features and Benefits

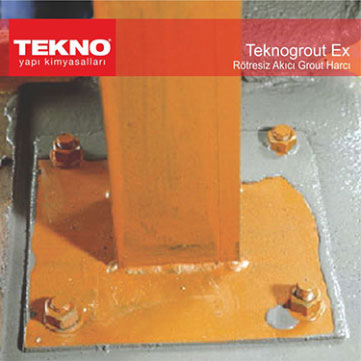

• Does not shrink, shows high fluency.

• Resistant to oils and acids.

• it is not toxic.

• Waterproof.

• Resistant to freezing and thawing.

• Resistant to various chemicals.

• Due to its very low VOC value, it is harmless to the environment and human health.

• it is resistant to heavy load impacts with its high mechanical strength.

• Flexible and powerful.

• High resistance at low temperatures.

• Soil moisture tolerance is high.

• Suitable cleaning with hat water

Uses

Can be used as long life and durable flooring products on many different surfaces and special areas such as food, medicine, cold stores, sanitary packaging and storages ares

Application lnstructions

The substrate must be clean, dry and free of all contaminants such as dirt, oil, grease, coatings and surface treatments, ete. lf in doubt, apply a test area first.

Teknobond 880 is applied as a thin layer as primer before application. The coating should be applied within a maximum of 24 hours after stripping primer. Epoxy primer is not recommended

The components are produced according to right mixing ratio. Mix the resin (component A) and hardener (component B) thoroughly with a mechanical mixer with a 400 - 600 RPM mixer in a clean container at least 3 minutes to have a homogenous mixture. Then add the well graded aggregate (component C) slowly, mixing all the time. Mix the three components at least 4 minutes to have a homogenous mixture.

Watchpoints

• Never thin by any solvent. Solvents will prevent proper curing and change mechanical properties.

• TEKNOBOND 880 has to be mixed with an appropriate mixing drill. Never mix with hand or trowel.

• Avoid application under temperatures below +5°C and over +30°C.

• Avoid application on frozen areas, on areas under risk of freezing in 24 hours or on areas open to direct sunlight or wind.

• TEKNOBOND 880 should be applied in 40 minutes (at 20°C). The workability and hardening times of polyurethane based products depend on temperature.

• After the application there should be no contact for 24 hours. Also water contact has to be avoided.

• Avoid splitting pre-batched units to mix. Mix complete units only.

• Component C must be kept dry.

• Cured material can only be removed mechanically.

Cleaning: Clean and tools and application equipment with Tekno Tiner immediately after use. Hardened / cured material can only be mechanically removed.