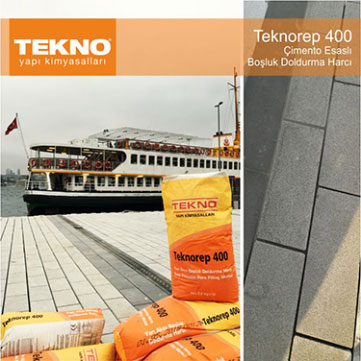

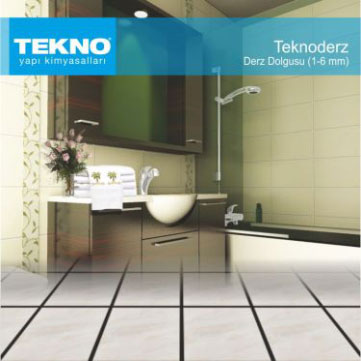

it is cement based, single component, fine, non-shrink, flowable jointing mortar.

it is cement based, single component, fine, non-shrink, flowable jointing mortar.Areas of Usage

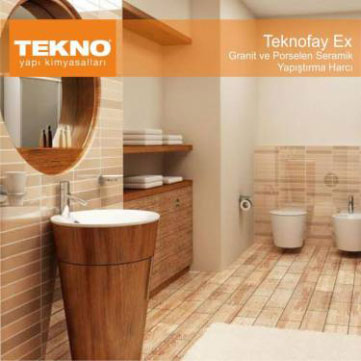

• lt's used to ensure that the parquet, granite and cubic stones are secured by filling the space between them,

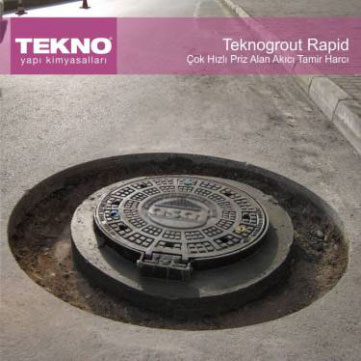

• in filling the pits in the small diameter chamber,

• in the joints of the cobblestone pavements and the veneer materials,

• in joints of city furniture and prefabricated elements.

Features and Benefits

• it is an easy to use material, made ready just by adding water.

• it can be used everywhere because there is very little shrinkage.

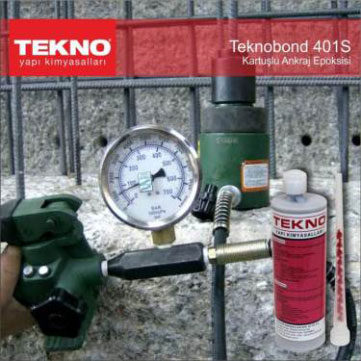

• Since it has very high adherence, it works monolithic with old concrete.

• Strength and abrasion resistance are high.

• it is resistant to oils and some chemicals.

• it is resistant to freeze-thaw cycles.

Application lnstructions

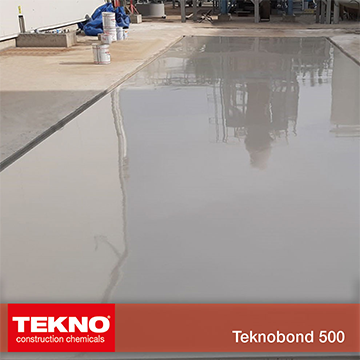

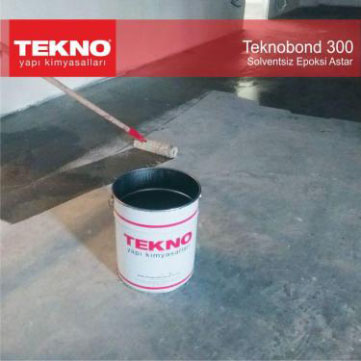

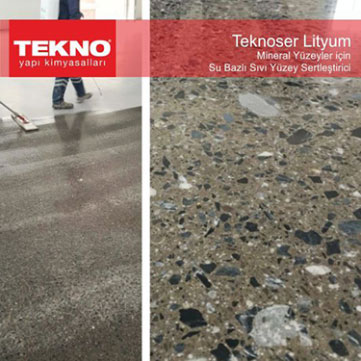

Surface Ouality: The surfaces must be clean, smooth, solid, free from any antiadhesive substance such as dust, oil, dirt, rust, mold oil, detergent and waste. Make sure that the surface of the stone to be cast is at the level of the stone and that the joints are in the desired fit.

Surface Preparation: Absorbent surfaces must be pre-wetted, but there should be no water accumulations. it would be more convenient to protect decorative and absorbent stone surfaces using TEKNOLATEX orTEKNOCILA before casting.

Mixing: 5,0-6,0lt clean, clear water received from normal ambient temperature into a clean container which is free from all kinds of materials which prevent adhesion. TEKNOREP 400 in 25 kg bag as powder is poured into a container filled with water. The product is mixed with a low speed mixer until a homogeneous mixture without lumps is obtained. Mixing time should be minimum 5 min. The mortar obtained at the end of the process should be rested for 3 min and mixed again until it becomes homogenous for 2 min. After the material has entered the reaction, it should not be mixed again with water.

Application Notes / Restrictions

• For outdoor applications, the first 3 hours of sunshine should be protected from rain and frost.

• in cement based products, reaction times are affected by ambient and ground temperatures. Reaction times are shortened in a hot environment, and extend in a cold environment.

• Hot mixture water should be used under extreme cold conditions.

• Cold mixture water should be used under extreme hot conditions.

• During the application of the product, work clothes suitable for occupational health and safety rules should be worn and appropriate glasses and masks should be used.

• it must be protected after application against adverse weather conditions such as direct sunlight, high air temperature (above +35 °C), rain and frost. The product should be cleaned thoroughly with water and detergent before it is fully cured and hardened.

• lmmediately after application, before hardened, the equipment should be cleaned with water. Afterthe product is hardened, it should be cleaned by mechanical methods.

• The prepared mortar is slowly poured into the joints. As another method, it can be done by pouring mortar and pulling it with a rust. The mortar spreads homogeneously to all sides because it is fluid. The better this processis, the harder it will be to spoil the joints and damage the floor covering (cobblestones,borders, cube stones, ete.).