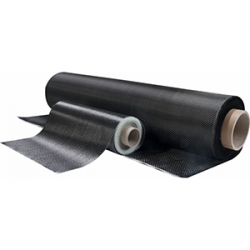

Carbon fiber is composed of carbon atoms bonded together to form a long chain. The fibers are extremely stiff, strong, and light, and are used in many processes to create excellent building materials. Carbon fiber material comes in a variety of "raw" building-blocks, including yarns, uni-directional, weaves, braids, and several others, which are in turn used to create composite parts. The properties of a carbon fiber part are close to that of steel and the weight is close to that of plastic. Thus the strength to weight ratio (as well as stiffness to weight ratio) of a carbon fiber part is much higher than either steel or plastic. Carbon fiber is extremely strong. It is typical in engineering to measure the benefit of a material in terms of strength to weight ratio and stiffness to weight ratio, particularly in structural design, where added weight may translate into increased lifecycle costs or unsatisfactory performance.

Carbon fiber is composed of carbon atoms bonded together to form a long chain. The fibers are extremely stiff, strong, and light, and are used in many processes to create excellent building materials. Carbon fiber material comes in a variety of "raw" building-blocks, including yarns, uni-directional, weaves, braids, and several others, which are in turn used to create composite parts. The properties of a carbon fiber part are close to that of steel and the weight is close to that of plastic. Thus the strength to weight ratio (as well as stiffness to weight ratio) of a carbon fiber part is much higher than either steel or plastic. Carbon fiber is extremely strong. It is typical in engineering to measure the benefit of a material in terms of strength to weight ratio and stiffness to weight ratio, particularly in structural design, where added weight may translate into increased lifecycle costs or unsatisfactory performance.Carbon fibers or carbon fibres are fibers about 5–10 micrometres in diameter and composed mostly of carbon atoms. Carbon fibers have several advantages including high stiffness, high tensile strength, low weight, high chemical resistance, high temperature tolerance and low thermal expansion. These properties have made carbon fiber very popular in aerospace, civil engineering, military, and motorsports, along with other competition sports. However, they are relatively expensive when compared with similar fibers, such as glass fibers or plastic fibers.

Classification and types

Based on modulus, strength, and final heat treatment temperature, carbon fibers can be classified into the following categories:

Based on carbon fiber properties, carbon fibers can be grouped into:

• Ultra-high-modulus, type UHM (modulus >450Gpa)

• High-modulus, type HM (modulus between 350-450Gpa)

• Intermediate-modulus, type IM (modulus between 200-350Gpa)

• Low modulus and high-tensile, type HT (modulus < 100Gpa, tensile strength > 3.0Gpa)

• Super high-tensile, type SHT (tensile strength > 4.5Gpa)

Based on precursor fiber materials, carbon fibers are classified into:

• PAN-based carbon fibers

• Pitch-based carbon fibers

• Mesophase pitch-based carbon fibers

• Isotropic pitch-based carbon fibers

• Rayon-based carbon fibers

• Gas-phase-grown carbon fibers

Based on final heat treatment temperature, carbon fibers are classified into:

• Type-I, high-heat-treatment carbon fibers (HTT), where final heat treatment temperature should be above 2000°C and can be associated with high-modulus type fiber.

• Type-II, intermediate-heat-treatment carbon fibers (IHT), where final heat treatment temperature should be around or above 1500°C and can be associated with high-strength type fiber.

• Type-III, low-heat-treatment carbon fibers, where final heat treatment temperatures not greater than 1000°C. These are low modulus and low strength materials.